The TAIROS Fertigbad system

The lightweight steel construction is a sustainable and future-oriented system for prefabricated bathrooms.

The design principle of TAIROS prefabricated bathrooms is based on a special lightweight steel construction. The lightweight steel construction of prefabricated bathrooms combines the advantages of low weight with high flexibility while meeting all requirements for rigidity and statics. This allows the building specifications to be implemented economically, efficiently and sustainably.

Advantages of TAIROS prefabricated bathrooms

- The special lightweight construction of the TAIROS prefabricated baths offers the advantage of its low dead weight (approx. 245 kg /sqm) while maintaining maximum stability of the entire system

- In times of lack of space and high prices per square metre in the big cities, more and more is being built up, and that's where the potential of lightweight construction lies

- Small wall constructions (approx. 40 mm) reduce the losses of square metre in the usable areas and even the smallest niches can be used optimally

- The low construction height (about 50 mm) of the floor element can be integrated into any floor structure

- Guaranteed quality through industrial production and constant quality control of the individual trades

- High work safety on the construction site, as equipment works are carried out at the factory. This results in a considerable reduction of the risk of accidents on the construction site

- Sanitary, ventilation, drinking water, sewage and electrical installations comply with the recognized rules of technology (DIN and EN standards)

- Requirements for sustainable construction are fulfilled

- The system design allows the flexible realization of various floor plans and bathroom variants. Complicated room designs and small series can be implemented

- Before each series production takes place the production of a sample bath

- The connection to the house installation takes place according to specifications of the consultants

- All from one hand; Complete planning and coordination of all trades involved in the bathroom (8-10 units). The TAIROS Fertigbad GmbH is the sole contact for a technically demanding unit in construction

- Simplified tendering and billing procedures

- Better schedule coordination due to less planning effort

- Relief of the construction manager

- The delivery of the finished bathrooms is always just-in-time. This saves working time and storage capacity on the construction site and ensures consistent working

- The low weight of the bath promotes simple construction site logistics and flexibility during installation and assembly. The introduction of the prefabricated bathrooms can be carried out with a normal construction site crane either with the shell construction step from above or via introduction openings in the facade

- Within the building, the prefabricated bathrooms can be moved at any time during the construction phase with a pallet truck

- Due to the low weight of the prefabricated bathrooms, the building can be planned statically optimized. This leads to cost savings and creative freedom in building planning

- Less weight means saving energy during production and logistics in building construction

- Shortening of construction times for architects and builders from two to three months

- Short downtimes, especially during modernization and refurbishment

Our System

The TAIROS prefabricated bathrooms are manufactured as torsion-resistant corpus and consist of three main assemblies.

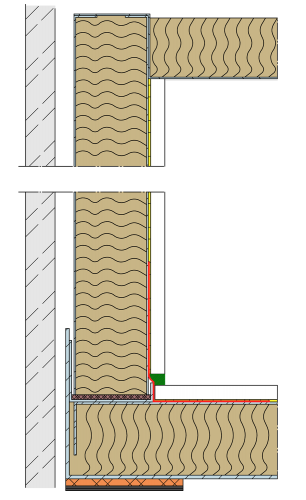

The walls are designed as self-supporting sandwich wall elements and equipped in the core with a sound and heat-insulating hard rock wool. To load the equipment objects reinforcing elements are installed in the walls. The small wall thickness of about 40 mm allows the optimal use of space reserves. Even the smallest niches can be designated as usable space. The connection of the walls takes place as a tongue and groove system and ensures maximum stability.

The water-impermeable multi-layer floor pan is equipped with a factory-ready gradient element for floor drainage. The self-made floor drain made of stainless steel guarantees optimum drainage performance and maximum safety with regard to mechanical stress. The floor element can be integrated into any floor structure due to its low height of approx. 50 mm. The installation of water-based or electric underfloor heating is possible.

The ceiling element is also designed as a sandwich construction. The inside of the ceiling is easy to clean and dirt-resistant thanks to the lacquered surface. In addition to lamps, other ceiling fixtures such as fans and revisions can be integrated.

Start your project together with us!

Benefit from the advantages of our constructions and involve us in your construction planning right from the start.